During the production process, dairy companies are using instruments to analyze the various products, such as milk, cheese milk and whey. In this way, they keep a grip on the production process and make adjustments where necessary. However, are the test results always correct? Many factors can be of influence of the test results. This includes sampling, pre-treatment of the sample, correct calibration, maintenance of the instrument and influence of the person who performs the analysis.

The Remote Dairy Quality tool has been developed within the Dairy Trial of the IoF2020 project. A valuable tool for dairy companies to improve efficiency through process optimization by obtaining accurate and assured analysis results.

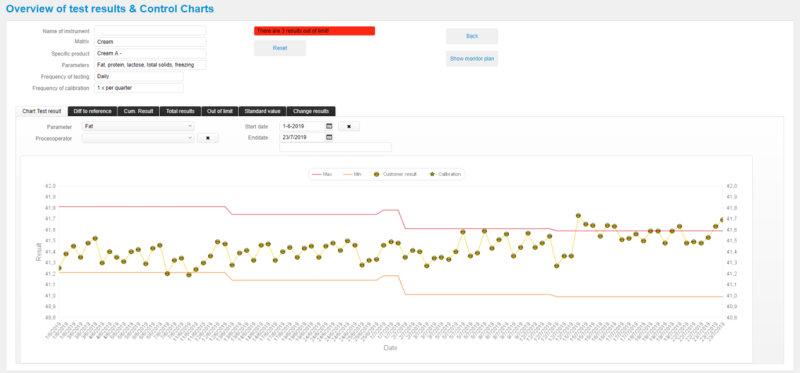

To achieve an improvement in efficiency, it is essential that a thorough control and calibration plan is made per instrument per dairy product. Next, the challenge is to implement it according to plan. With this tool, control and calibration plans are set up and the implementation of the plan is monitored. With RDQ, the method of pretreatment of the control samples and whether the analysis results of the control samples fall within the set limits is all recorded. All this is presented graphically in digital control charts and deviations are reported to the responsible person by means of alerts. The RDQ tool is available online for the various employees, such as process operators, QC and QA managers, regardless of location. If more than one person carries out the analyzes of the control samples, it is possible to follow the performance of each individual employee.

The RDQ tool is already being used successfully by customers in practice at multiple locations within the Netherlands. Several users analyze different types of dairy products, such as milk, skimmed milk, cream and various whey products. The RDQ tool hereby guarantees that the analysis results are accurate and guaranteed. These test results form a reliable basis for producing final-products that meet the specified specifications for fat, protein and lactose and improve efficiency of production.

Currently the RDQ-tool is promoted to dairy processors within Europe.

IoF2020 has received funding from the European Union’s Horizon 2020 researchand innovation programme under grant agreement no. 731884”